STORAGE OF RENEWABLE ENERGY [CNG] AT HIGH PRESSURES

In 2022, India became the fourth largest country in the world by valuation of the automotive industry. With this massive influx of automobiles, India is leaning towards Compressed Natural Gas (CNG) as a significant renewable energy variant. CNG as a fuel helps curtail emissions from traditional fuels such as diesel and petrol. India’s projected sales of CNG vehicles will increase from 863.22 thousand units in 2021 to 1,463.46 thousand units by 2029.

Government Initiatives to Promote CNG Vehicles:

- Individual states are investing heavily to build a CNG infrastructure.

- Keeping the price of CNG lower than traditional fuels prompt customers to see it as a cost-saving option.

- SATAT Scheme for producing automobile-grade CNG from biogas generated from waste.

The segment was dominated by passenger vehicles; sales of CNG accounted for 12.1 percent of sales at 177,410 units as against 120,070 units in 2021; carmakers are betting on CNG in a big way as it gives owners a more affordable driving option. The top CNG car manufacturers are Maruti Suzuki, Tata Motors, Hyundai, Bajaj & Mahindra.

Infrastructure:

One of the critical elements to support this boost in sales will be technology in the form of safer storage for this flammable gas at higher pressures. CNG is stored at 250 barg pressures in the cascades at filling stations and transferred into smaller cylinders, cars, buses, etc.

CNG Cylinder Types and Manufacturers:

CNG tanks can be categorized into Type 1, Type 2, Type 3, and Type 4. The type is determined primarily based on design, production method, and liner material. Generally, in India, Type 1 Cylinder comprises all steel, which is relatively economical and heavier. The varying capacity of 30 L, 60 L, and 90 L cylinders are used in 3-wheelers, cars, trucks, and buses.

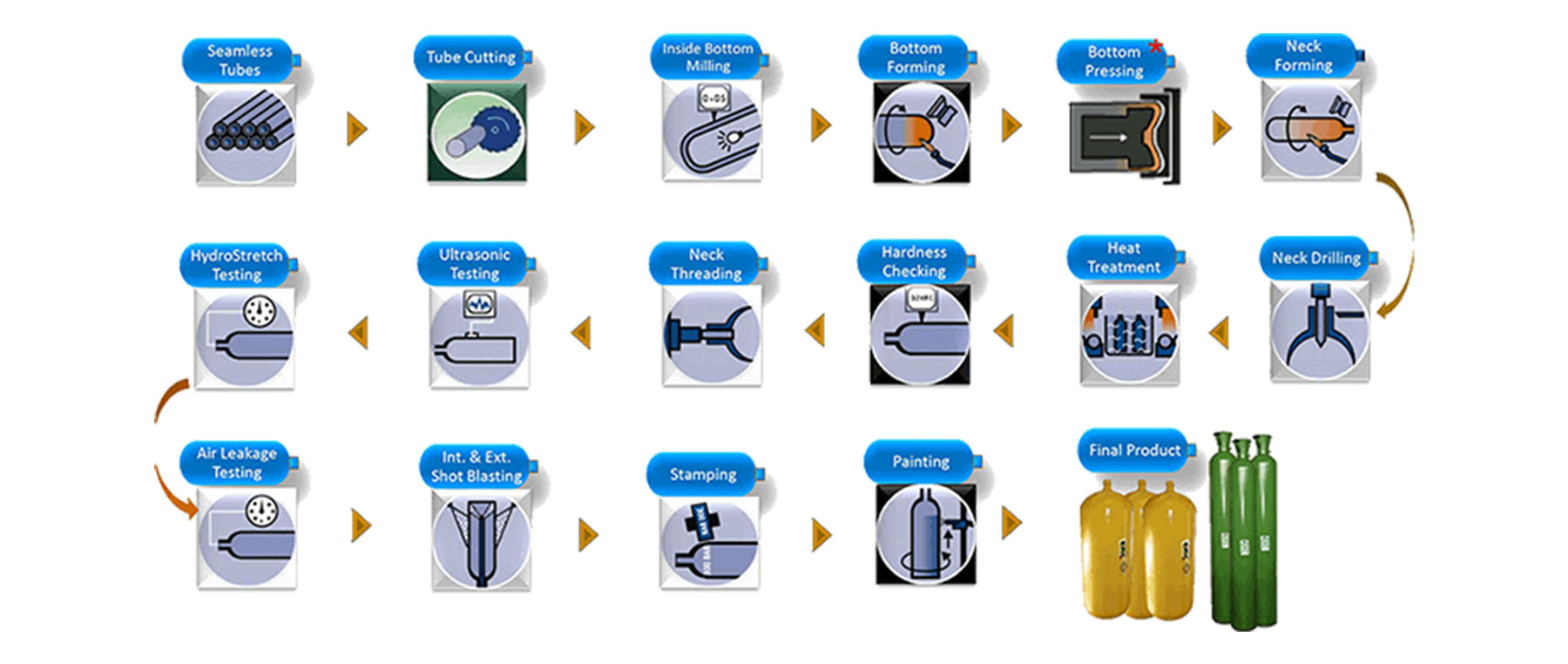

CNG Cylinder Manufacturing Process: The manufacturing process is showcased in the flow diagram below:

Use of Compressor:

A high-pressure compressor is used in a very critical stage of the manufacturing process. The air leakage test is one of the final, conclusive tests wherein the cylinder's integrity is checked before it is given a clean chit for dispatch. Compressed air at 400 barg pressures and 200 m3/hr flows are generally required for the process.

COMPRESSORS SOLUTIONS FROM ELGI SAUER RANGE FOR CNG CYLINDER TESTING APPLICATION:

Suction pressure: max. 16 bar g

Final pressure: max. 500 bar g

Volume Flow Rate: max. 500 m3/ h

Rated Power: max. 75 kW for Air

ORKAN series compressors are based on a flexible modular system and cover a wide output range.

- High-pressure air compressors up to 500 barg

- Real gas boosters with inlet pressures of up to 16 barg

- Hermetically gas-tight designs with magnetic coupling

- Standard products for air, nitrogen, helium, CNG, and hydrogen

- Ex-proof versions acc. to ISO 80079-34:2018 and the European ATEX directive 2014 / 34 / EU

Magnetic coupling drives for Gas Boosters.

Orkan gas boosters feature Sauer's first magnetic coupling drive for hermetically gas-tight compressors. It guarantees absolute gas tightness, is extremely low maintenance, and operates with maximum reliability.

CubeCooler

The new CubeCooler enables re-cooling temperatures more than 30% lower than conventional cooler configurations. Coolers have been arranged radially around the combined fan and flywheel for a high cooling capacity like this.